Flow Calculations

Guttering Flow Calculations Guide

If you are going to fit your guttering on your own, we have created this guttering flow calculations guide to make your job as easy as possible. For any further queries, please feel free toget in touchwith us.

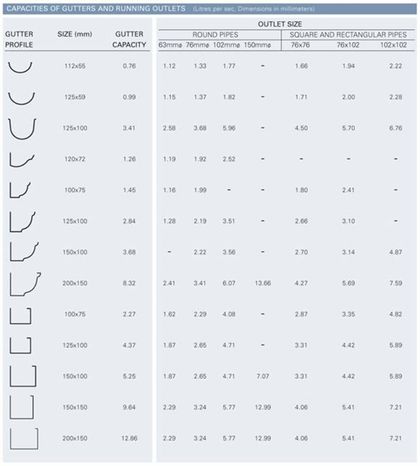

Notes on Flow Capacities Chart

Design capacities calculated in accordance with BS EN 12056-3.

Distance between stop end and outlet should not exceed 50 x depth of gutter, and distance between outlets should not exceed 100 x depth of gutter.

Attention is drawn to Para 8.3.2 and Fig.3 of the above BS Code of Practise: i.e. careful placing of outlets enables smallest practicable gutter sizes to be used.

For the same total flow (Q), the gutter in Fig.A requires half the capacity of the gutter in Fig.B. Outlet capacities remain the same.

Similarly:

For the same total flow (Q), the gutter in Fig.C requires half the capacity of the gutter in Fig.D. Outlet capacities remain the same.

Where the length (Lg) of an eaves gutter is more than 50 times its overall depth (d) the following reduction factors should be applied.

Where the length (Lg) of an eaves gutter is more than 50 times its overall depth (d) the following reduction factors should be applied.

Lg/d Reduction Factor

- 50 1.0

- 100 0.93

- 150 0.86

- 200 0.80

Lg = either the distance between stop end and outlet, or half of the distance between two outlets.

Where a corner is near to an outlet a further reduction factor should be applied.

Less than 2m from outlet: reduction factor = 0.8

Between 2m and 4m from outlet: Reduction factor = 0.9 6.

Apparent anomalies can occur in the capacities chart as discharge characteristics change from 'weir' to 'orifice' type.

Calculations

Designs are based on rainfall rate of 79mm/hr.

Therefore RUN-OFF RATE (l/s) =EFFECTIVE AREA m² x 0.022

Effective roof areas can be calculated as follows (from Building Regulations):

Type of Surface Design area (m²)

Flat Roof Plan Area of Relevant Proportion

30° Pitch Roof Plan Area of Relevant Proportion x 1.29

45° Pitch Roof Plan Area of Relevant Proportion x 1.50

60° Pitch Roof Plan Area of Relevant Proportion x 1.87

Simple Example

X = 5m, Y = 10m

Angle of roof 30°

System required: Moulded Ogee with round pipe.

Design Area ('Effective Area') = 5 x 10 x 1.29 = 64.5m²

Run Off = 64.5m² x 0.022 l/s per m² = 1.42 l/s

From chart, 125 x 100 gutter with 76 Ø downpipe appears suitable, but check:

Lg = 10 = 133 therefore reduction factor = 0.86 D 0.1

Gutter capacity x reduction factor = 2.84 x 0.86 = 2.44 l/s, therefore the proposed system is suitable.

Calculations

Designs are based on rainfall rate of 79mm/hr.

Therefore RUN-OFF RATE (l/s) =EFFECTIVE AREA m² x 0.022

Effective roof areas can be calculated as follows (from Building Regulations):

Type of Surface Design area (m²)

Flat Roof Plan Area of Relevant Proportion

30° Pitch Roof Plan Area of Relevant Proportion x 1.29

45° Pitch Roof Plan Area of Relevant Proportion x 1.50

60° Pitch Roof Plan Area of Relevant Proportion x 1.87

Simple Example

X = 5m, Y = 10m

Angle of roof 30°

System required: Moulded Ogee with round pipe.

Design Area ('Effective Area') = 5 x 10 x 1.29 = 64.5m²

Run Off = 64.5m² x 0.022 l/s per m² = 1.42 l/s

From chart, 125 x 100 gutter with 76 Ø downpipe appears suitable, but check:

Lg = 10 = 133 therefore reduction factor = 0.86 D 0.1

Gutter capacity x reduction factor = 2.84 x 0.86 = 2.44 l/s, therefore the proposed system is suitable.

Fixing Advice

When installing our high capacity gutters there is no requirement (with the exception of the small half rounds) to fix to falls. The majority of rainwater systems are fixed nominally level. All half round systems must be installed by external fascia brackets.

Fixing Support Centres

Aluminium Moulded Ogee gutters only 600mm - 750mm maximum; extra fixing points on either side of all fittings.

External/Internal Support Brackets

Aluminium Half round gutters: brackets at 750mm centres; extra fixing brackets on either side of all fittings.

Moulded Ogee gutters: brackets at 750mm centres; extra fixing brackets on either side of all fittings.

Box gutters:

brackets at 750mm centres; extra fixing brackets on either side of all fittings.

Non-standard gutters:

bracket centres dependant on girth and profile. Consult Northwest seamless Technical Services Department.

Snow Loading

In locations where there is a probability of excessive snow loading both and external and internal support bracket should be installed.

Gutter Jointing

Clean then dry all jointing areas with a low alkaline degreasing agent. Apply a generous bead of low modulus silicone sealant, e.g. Dow Corning, to BS EN ISO 11600:2003+A1:2011 or similar approved, to the internal base and sides of the gutter profile. Place the connecting collar in position and align with corresponding fixing bolt holes. Evenly tighten the nuts starting at the base of the gutter. The silicone will be compressed and displaced into the bolt holes and between the gutter and the connecting collar. Clean away excess silicone and repeat the same procedure on all joints and fittings.

Pipe Jointing

All rainwater pipe sockets are of a light drive fit, apply a light bead of silicone to the internal aperture inside the socket prior to connection. This will provide a permanent flexible seal and prevent any leakage from capillary action.

Fixings and Fasteners

Use only aluminium and stainless steel fasteners for the installation of the following:

Gutters:

Direct and bracket fix use 12x40mm round head screws and washers.

Use 6mm mushroom head bolts, nuts and washers.

Gutter joint fixings:

Pipe fixings:

For fixing of eared pipe sockets and pipe brackets use either a 6mm expanding bolt or a 12x50mm round head screw and plug.

Fascia/soffit fixings:

Use 12x40 or 12x50mm round head screws and 6mm mushroom head bolts, nuts and washers, length to suit application. All fixings, fasteners, sealant and touch-up paint are available from Northwest seamless.

If you would like additional guidance on our guttering flow calculations guide, please do not hesitate to get in touch with GutterTech UK, based in Great Harwood, Blackburn, today by calling us on the number below.

01254 884 020

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later

Share

Tweet

Share

Mail

© 2024. The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.